Superior® Locker Accessories

- - 6" Closed Front Base (KD lockers only): Shall be fabricated of 16 gauge cold rolled sheet steel flanged on all four sides for rigidity. Front bases include projecting tabs on side flanges designed to align with holes in front legs allowing front bases to be snapped into place requiring no additional fasteners. Side bases are to be included at all exposed ends and are bolted to front and rear legs. Finish to match lockers.

- - 4" Continuous Z-Base (KD lockers only): Shall be fabricated from 16 gauge cold rolled sheet steel fabricated in 72" lengths, flanged at the top to form a 1-3/8" toe space and at the bottom allowing concealed fastening to the finished floor. Continuous Front Bases include holes for use with splice plates where bases are joined end-to-end. End Bases are to be included at all exposed ends. Where additional support is desired, End Bases may be substituted for splices at Continuous Front Base joints. Finish to match lockers.

- - 20 gauge Individual Slope Top (KD lockers only): Not less than 20 gauge cold rolled sheet steel, 18 degree pitch, fabricated to be installed individually over each locker. Slope top is formed to include a full back. Individual Slope Tops are to be installed in addition to the locker flat top. End closures are to be provided at exposed ends. Finish to match lockers.

- - 18 gauge Continuous Slope Top: Not less than 18 gauge cold rolled sheet steel, 18 degree pitch, in 72" lengths. A splice cover with concealed spring clip is to used to cover joints where Continuous Slope Tops are joined end-to-end. To be installed in addition to the locker flat top with end closures for support. Finish to match lockers.

- - 16 Gauge Continuous Slope Top: Not less than 16 gauge cold rolled sheet steel, 18 degree pitch, in 72" lengths. A splice cover with concealed spring clip is to used to cover joints where Continuous Slope Tops are joined end-to-end. To be installed in addition to the locker flat top with end closures for support. Finish to match lockers.

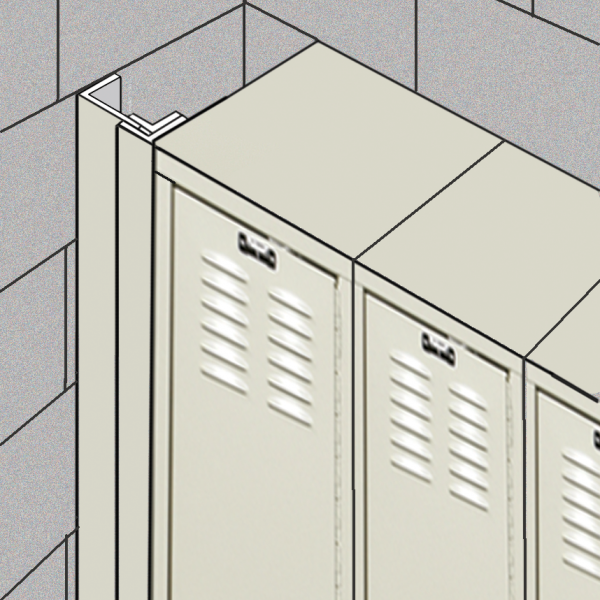

- - Recessed Trim: Fabricated of 16 gauge cold rolled sheet steel. 3" wide side trim shall be notched at the top and include a retainer to allow the 3" wide top trim to fit snugly into the side trim. Recess trim is designed to be used when the lockers are installed with the locker fronts flush with the top and side walls. The top and side trim will project 3/8" beyond the side and top walls and include return bends back to the walls. Finish to match lockers.

- - Minimum Punched End Panel (KD lockers only): Shall be from 18 gauge cold rolled steel and formed to fit tightly over the universal side panel at exposed row ends. Holes are provided at perimeter for fastening to locker. Minimum Punched End Panels are designed to cover all fasteners other than those at the perimeter of the panel. Finish to match lockers. Provide at all exposed ends.

- - Boxed End Panel: Shall be "Boxed" type formed from 16 gauge cold rolled steel with 1" O.D. double bends on sides and a single bend at top and bottom with no exposed holes or bolts. If lockers have slope tops, end panels must be formed with slope at top to cover the ends of the slope tops. Finish to match lockers. Provide at all exposed ends.

- - Fillers: Provide where indicated, of not less than 16 gauge cold rolled sheet steel, factory fabricated and finished to match lockers.